Diosna Dierks & Sohne GmbH

Raking in the dough

Following its takeover of pre-dough specialist Isernhager in January 2015, machine manufacturer Diosna Dierks & Sohne GmbH now holds a coveted position in the market as the only provider of complete dough production including biotechnology

Privately owned German company Diosna Dierks & Sohne GmbH has been involved in the food industry since 1885, when its founder, Friedrich Dierks, and a partner, established the firm for the fabrication of machines for farming and creameries. Over the years the company developed a steady stream of innovative mixers for both the pharmaceutical and bakery industries, two strategic business segments that it has retained a strong presence in today. Elaborating on the company’s rise in dough production is CFO and Head of Bakery Division Henrik Oevermann: “In the bakery division we focus on dough products, including the biotechnology and equipment for fermentation of dough and the mixing of dough. We are focused on both big industrial bakers and small artisan bakers, as processes are the same.”

With the remaining shares of Diosna sold by the family in 1997 to Multimixing SA, a French holding company that was acquired by Group Breteche in 1998, Diosna further launched some innovative developments like the Premium Range mixers in stainless steel and the Bottom discharge mixers.

Renowned as a leader in kneading machinery, the company develops each Diosna product individually to ensure its bakery machines are a perfect fit for the production process of any bakery. “As atypical German champion, we lead the way with regards to quality and always have our teams striving to improve the products we create. We also focus a great deal on service; we have our service structure with service hubs and partners across the globe, which makes us highly reliable. Ultimately, we say what we do and we do what we say,” highlights Henrik.

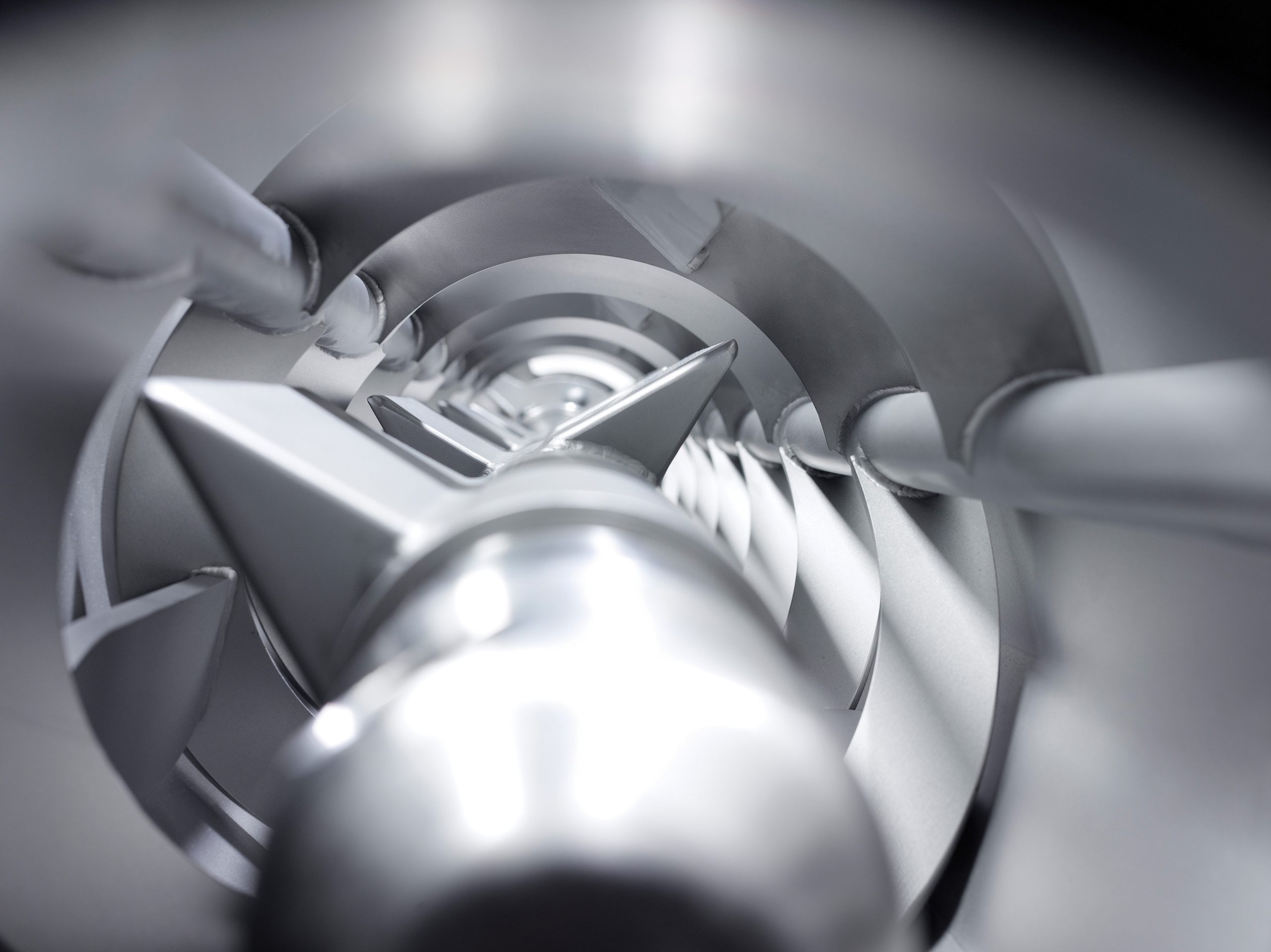

Furthermore, Diosna achieves an ideal dough due to the optimal mixing conduct of its machines, which thus results in a solution for all kinds of doughs. Indeed, with a Diosna product, the amount of dough or hourly output are not important for an ideal result; instead, these bakerymachines obtain perfect kneading results even with challenging kinds of doughs like wheat or brown bread. “One product within our bakery range that I would like to highlight is the ContinoMIXX, a machine that has a patented solution tocontinuous mixing thanks to its inner tool, which operates in one direction, and an outer tool that operates in the opposite direction. It is somewhat superior to other solutions in the market and has the potential to be used for all of the food industry,” says Henrik.

Made from stainless steel, the ContinoMIXX has been specially developed for use with high quality wheat-based and mixed dough to mix raw materials into a finished dough. Thanks to its twin-screw mixing machine, a particularly smooth mix can be produced by the ContinoMIXX, while the twin-screw kneading machine operates along the entire feed length to create a controllable and intense dough-kneading process.

Not content with its already strong presence in the production of dough, Diosna took the strategic decision of taking over the entire shares of predough specialist Isernhaeger in January 2015, which has provided the company with a unique platform to provide complete dough production. From the dosage and pre-dough preparation, the Isernhaeger products for pre-dough bio-technology, processing and the kneading, all the way up to the handoverlogistics such as belts and elevator tippers, both organisations now provide the comprehensive range of dough competence, putting them in a globally unique market position, as Henrik discusses: “Our history as Diosna has always been more connected to equipment and machine manufacture, with our revenue more or less linked to the sale of equipment. With Isernhaeger and its supply chain, we are now progressing into process equipment and bio-technology for fermented pre-dough.

“Looking into the strategic reasons behind this takeover, we now have atriangle of success that is comprisedof an equipment corner, a biotechnical area and a process and automation area. Traditional Diosna is the equipment corner, while Isernhaeger is the biotechnical corner as it has the raw materials to process the food on an industrial scale, while process and automation is all about the process required to specific biotechnology, specific ingredients and the equipment. This strategic triangle is not only superior to our former method of operation, but also an USP to our customer, who needs all parts of the triangle.”

Along with the obvious benefits of the takeover came the merging of employees, with 45 members of Isernhaeger’s staff added to Diosna’s site. “If you merge a machine manufacturing company with abiotechnical and process company there is always a lot to learn on both sides of the hierarchy,” states Henrik. “We are working with experts and biotechnologists and have also hired a number of dough technologists who are able to create new recipes and new products with the customer on a large scale without sacrificing quality.”

Aware that customers want the perfect product, Diosna is now able to deliver bespoke solutions in accordance with its clients specifications, as Henrik highlights: “We have had a lot of enquiries for integrated pre-dough and dough production as we are able to define the complete process. For example, two to three months after the merger we sold our first installation in Turkey, where a customer was interested in using our integrated technology.”

As consumer markets in locations such as Asia, the Middle East, Africa andAmerica are shifting from rice to wheat products, the future looks increasinglypositive for Diosna as it focuses on implementing its strategy to the customer by showing the benefits of working with dough experts that can deliver a turnkey solution. “Ultimately, we want to be dough experts, delivering consumer guaranteed best bakery products all over the world,” Henrik concludes.