How Inline Plastics is thinking outside the box

At Inline Plastics, it’s all about the customer’s complete satisfaction and the delivery of exceptional products and service. The manufacturer of thermoformed plastic food packaging operates five strategically located facilities across the United States, ensuring that the right products are produced exactly where and when they are needed, regardless of location.

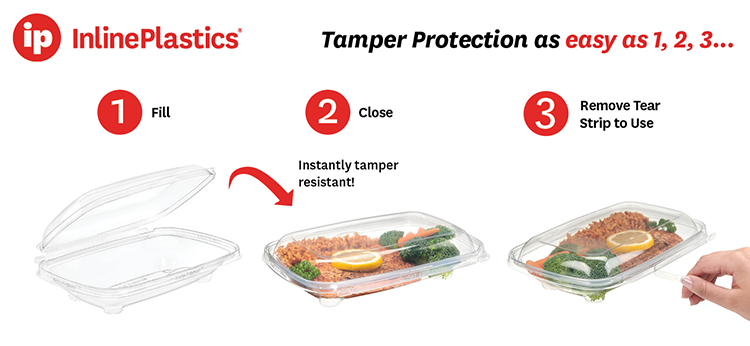

With over half a century of experience, Inline Plastic’s longevity is a result of constant innovation, developing new features and solutions to industry problems. The company is recognized as a leader and innovator in the food packaging industry, known for its commitment to developing cutting-edge, tamper-protection. It continually pushes the boundaries of packaging design and technology, ensuring products meet the evolving needs of customers. Inline Plastics is setting new standards in both product quality and environmental responsibility.

With over half a century of experience, Inline Plastic’s longevity is a result of constant innovation, developing new features and solutions to industry problems. The company is recognized as a leader and innovator in the food packaging industry, known for its commitment to developing cutting-edge, tamper-protection. It continually pushes the boundaries of packaging design and technology, ensuring products meet the evolving needs of customers. Inline Plastics is setting new standards in both product quality and environmental responsibility.

For years, Inline Plastics has been at the forefront of development that prioritizes safety, freshness, and convenience. The company’s R&D team faced the challenge of adapting these features to a new substrate that could protect ‘heat & eat’ meals and hot food applications. The result was Safe-T-Chef®, the first polypropylene, all-clear, product line featuring the company’s patented tamper protection technology. This breakthrough impressed processors, retailers, and consumers alike. Today, the product line has grown to include 22 versatile shapes and capacities, with more on the way.

In today’s fast-paced food service industry, there is an increasing demand for food safety, freshness, and enhanced convenience. Safe-T-Chef® delivers high clarity and durability, making it the perfect solution giving consumers confidence that their food has remained secure. The Safe-T-Chef® product line has expanded to include anti-fog technology across all vented options. Since consumers often make purchasing decisions based on visual appeal, it is essential that the presentation of the food remains impeccable. When hot food is packaged and placed under heat lamps or in display cases, venting alone may not be enough, leading to fog that obscures the view of the food. The addition of anti-fog eliminates this issue, providing a clear view of the vibrant colors and appetizing presentation.

secure. The Safe-T-Chef® product line has expanded to include anti-fog technology across all vented options. Since consumers often make purchasing decisions based on visual appeal, it is essential that the presentation of the food remains impeccable. When hot food is packaged and placed under heat lamps or in display cases, venting alone may not be enough, leading to fog that obscures the view of the food. The addition of anti-fog eliminates this issue, providing a clear view of the vibrant colors and appetizing presentation.

Another addition to the product line is the flat lid option, designed for applications where extra headspace is not required. While the dome-style lid allows for more headroom for bulkier contents, the flat lid offers a fuller appearance for more compact items. This option is perfect for optimizing limited shelf space, especially in areas with constrained shelving.

The current marketplace demonstrates a universal preference for transparent, clear packaging. Consumers want to see their food, and the recycling industry prefers it for ease of sorting and processing. To meet those goals, Inline Plastics created the all-clear, 360o, smooth wall container. This design allows for an appealing presentation that is also extremely user-friendly, as polypropylene is safe for both microwave and dishwasher use. Consumers can also serve and eat food directly from the container without the need to transfer it to another plate or dish.

Click to Learn More about Safe-T-Chef

Sponsored by Inline Plastics