Transforming supply chain sustainability with automation

Sustainability has become a must in the food supply chain, as businesses work to comply with growing regulations, attract eco-conscious consumers, and do their part to protect the planet. Across the food industry, we’re seeing investments in technologies to support sustainable practices from the farm down to the retail level.

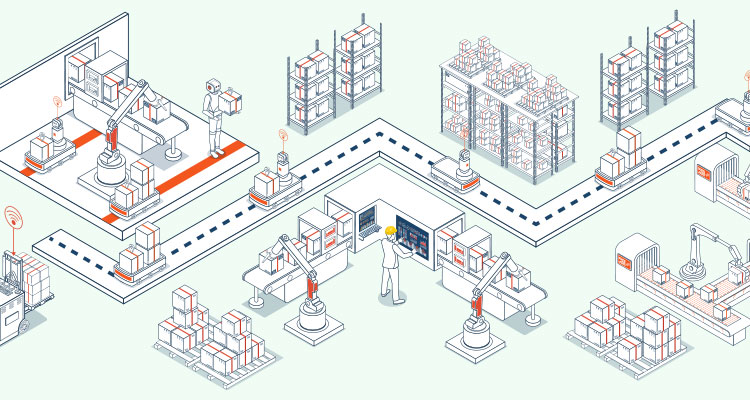

In warehousing and distribution, food businesses are making significant strides in sustainability through automation. Traditional logistics practices rely heavily on inefficient operations that lead to excess food waste, resource consumption and carbon emissions. Now, automation is revolutionizing how food moves from farm to table, enabling food companies to tackle their biggest environmental challenges.

inefficient operations that lead to excess food waste, resource consumption and carbon emissions. Now, automation is revolutionizing how food moves from farm to table, enabling food companies to tackle their biggest environmental challenges.

Fighting food waste

Food waste is one of the biggest environmental issues today. In the United States alone, more than one-third of food produced for human consumption ends up as waste, and food is the largest category of material sent to landfills. As food waste decomposes, it produces massive amounts of greenhouse gas: the equivalent of driving 54 million cars.

While there are many factors that contribute to food waste within the supply chain, it is commonly caused by delays during distribution. Traditional logistics processes are far too slow and inefficient for fresh food handling, significantly increasing the likelihood of spoilage and waste. To combat this issue, food companies are implementing modern automated solutions within their production facilities and distribution centers (DCs).

Today’s automated solutions integrate robotic storage and order picking technology into one fast, seamless operation. The solutions rapidly and accurately move perishable food products through the entire distribution process, from receipt and storage to order picking and dispatch. Automation’s high speed and precision directly translate to shorter lead times, minimizing the chance of spoilage during transportation and ensuring fresh food lasts longer in consumers’ homes.

Reducing energy consumption

Beyond addressing the food waste problem, automation is improving sustainability through energy efficiency. Today’s automated systems are built for low energy consumption. They optimize each step food products take through distribution, minimizing unnecessary movements and conserving energy.

While there are many kinds of automated systems on the market, gantry-style solutions are one type that’s ideal for energy efficiency. Designed for overhead product handling, gantry robots are made from lightweight, durable materials like aluminum. This design allows them to make quick and precise movements, while offering the strength to handle multiple crates or cases of food at the same time for added efficiency. Some gantry-based solutions even incorporate regenerative braking technology, allowing the system to recover approximately 30 percent of energy and feed it back to the power grid.

When it comes to constructing new distribution facilities, food businesses can reduce future energy needs by utilizing space-efficient automation. High-density automated storage solutions require half as much space as a traditional setup, enabling companies to design their ideal DC within a much smaller footprint. These scaled-down facilities will be able to handle as much capacity or more than a typical DC, while requiring much less energy for lighting, heating, and cooling.

Tackling air pollution

Greenhouse gas emissions are another major environmental concern for the food industry. While ground transportation is necessary for moving shipments through links in the supply chain, delivery trucks and vehicles generate CO₂ and other greenhouse gases that contribute to pollution and climate change. Fortunately, automation can drive improvements within the DC that reduce transportation emissions out on the road.

Managed by an intelligent Warehouse Control System (WCS), automated order fulfillment solutions can build route-friendly outbound orders, and they can load pallets efficiently within delivery vehicles to make the best use of available truck space. By optimizing how products are packed and routed to stores, food distributors can deliver greater order volumes while using fewer trucks and driving fewer miles. They ultimately reduce fuel consumption and greenhouse gas emissions, while staying on top of deliveries.

Building transparent supply chains

Improving traceability is crucial in today’s food supply chain. Companies need to maintain detailed records of product origins and track their movements from raw material suppliers to final deliveries. Automation is proving to be an essential tool for supporting traceability within distribution facilities and across the supply chain.

As food moves through distribution facilities, automated logistics solutions accurately capture critical traceability data for every single product. Information such as product origins, batch numbers, and destination details get stored and maintained by the systems’ software, and this data can be leveraged to support sustainability goals.

Through data analysis, companies can identify opportunities to reduce waste and conserve resources. With complete visibility upstream, they can ensure they only source ingredients from farms and suppliers that employ sustainable and ethical practices. Moreover, companies can pass information on product origins down to consumers, encouraging shoppers to make environmentally and socially conscious purchasing choices.

Creating sustainable food supply chains for the future

Automation is already putting today’s food businesses on the right track to sustainability, and the technology will only continue to evolve. As we see automated solutions incorporate powerful tools like artificial intelligence (AI), the industry will have unprecedented opportunities to create an environmentally friendly food system and a healthier planet for generations to come.

For a list of the sources used in this article, please contact the editor.

Mikko Peltomäki

Mikko Peltomäki is Director of Business Development at Cimcorp, where he drives strategic growth and market expansion. With expertise in automation and supply chain optimization, he helps businesses enhance efficiency through cutting-edge robotic solutions. Mikko focuses on forging partnerships and delivering intelligent automation to streamline operations in today’s evolving logistics landscape. Since 1975, Cimcorp has been simplifying material flows to enhance efficiency and profitability for businesses worldwide. As a member of Murata Machinery Ltd., one of the world’s largest logistics automation suppliers, the company leverages a global network of offices and partners to offer local support with an international foundation.