Compaxo Fijne Vleeswaren

Meeting demands

Despite both old and new challenges, Compaxo Fijne Vleeswaren continues adding to over 100 years of success in the meat industry

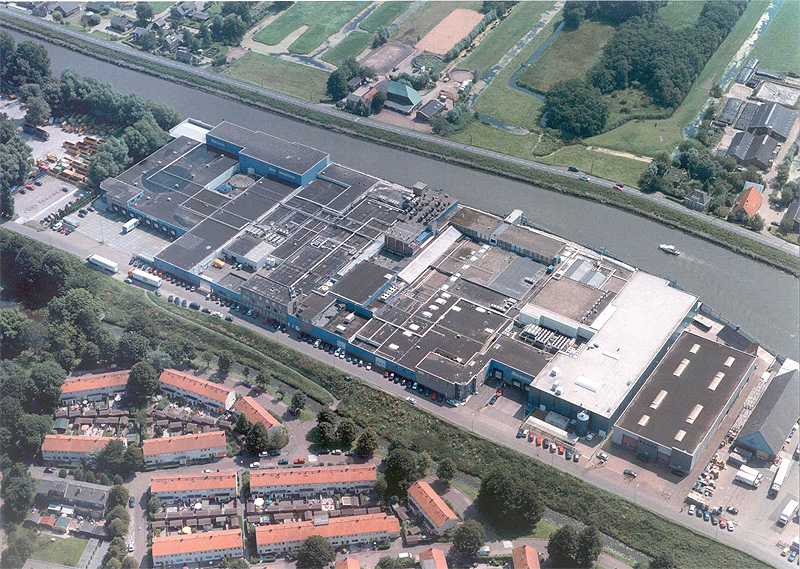

A butcher’s shop was established in Gouda, the Netherlands, in the latter half of the 1800s that was passed from father to son. In 19 the family relocated to a local industrial estate where a factory was established and, through the 1960s and 1970s, grew into a major undertaking. Today, Compaxo Fijne Vleeswaren remains the ownership and responsibility of the van der Post family and runs two factory sites, supplying pig-derived meat products to supermarkets and industrial consumers throughout Europe.

With the factory in Gouda still operational, the company has established a second factory at Zevenaar in eastern Holland. The two sites specialise in different areas of the company’s operations: Zevenaar is Compaxo’s slaughterhouse and responsible for the processing of 30,000 pigs per week, whilst the factory at Gouda now functions as a sausage-making plant, manufacturing 500 tonnes of produce over the same time period. Of this output, the company markets 300 types of product in 1200 different varieties of packaging.

With the factory in Gouda still operational, the company has established a second factory at Zevenaar in eastern Holland. The two sites specialise in different areas of the company’s operations: Zevenaar is Compaxo’s slaughterhouse and responsible for the processing of 30,000 pigs per week, whilst the factory at Gouda now functions as a sausage-making plant, manufacturing 500 tonnes of produce over the same time period. Of this output, the company markets 300 types of product in 1200 different varieties of packaging.

Gerard van der Post, one of the current proprietors of Compaxo and great-grandson of the original butcher shop’s owner, explains further the customers to whom Compaxo delivers: “Direct from our slaughterhouse we serve factories across Europe who process our meat into items for their local market. These customers are located in France, Germany, Italy and Belgium, as well as other regions throughout Europe. Also, attached to the slaughterhouse, we have a bacon curing operation where we cure 250 tonnes of bacon weekly specifically for the UK market.”

He continues: “From the sausage factory, about 85 per cent of its 500 tons ends up in the domestic market, delivered to all the supermarkets which are located in the Netherlands including Albert Heijn, C1000 and Super de Boer. The rest of the meat is exported to various countries including Belgium, the UK and Germany.”

The quality of Compaxo’s products and the reliability of its service can be seen in the extent of its working partnerships. It has been supplying Albert Heijn since the 1950s when the business was relatively small; today Albert Heijn is the country’s largest supermarket chain and Compaxo remains one of its leading suppliers for pork. This is just one of a number of longterm relationships that the company is involved with.

To maintain this sort of success, the company considers one of its main strengths to be the fact it remains a family company. All seven senior executivesof the company are of the van der Post genealogy, whilst a further ten children of those seven executives have begun working at the factories alongside the company’s 750 other staff. The seven executives have gained between 30 and 45 years’ experience in the company and, as with all family employees, began on the factory floor before working

Gerard discusses why this helps Compaxo succeed: “A lot of our employees have been working with us for many years, so you’re always working with the same people that know how to do the job. Many of the companies around Europe, particularly the major ones, have a huge staff turnaround and that makes the company very inconsistent. I believe that because we have long-term staff, that some of us have been here 30 years or more, we know the business, the products and our customers.”

Despite its heavy emphasis on tradition, Compaxo is not a company afraid of modernisation and development. It engages in a continuous process of upgrading the entire operational process, from modernising equipment to utilising new production techniques. The slaughterhouse at Zevenaar is currently undergoing a major refurbishment programme that sees not only the installation of new machinery but also the addition of new buildings to the plant. This upgrade will cost anything from 200,000 to 800,000 euros per building. Furthermore, the family is currently investing in the development of new systems that will enable the manufacture of as-yet-uncommon produce.

This ongoing effort to remain up-to-date is essential for the company to remain a key player in the market. With competitors coming in a variety of forms, from the way companies like McDonald’s have shaped the meat production market to the emerging industrial regions of East Europe having cheaper product available, a small company such as Compaxo has to offer something its competitors do not. Of course where Compaxo excels is in the quality of its meat.

Part of this quality is derived from the owners’ long experience in the market. Another factor is the company insists on its suppliers adhering to the Integrated Chain Control (IKB) quality assurance scheme. Furthermore, 25 per cent of the company’s stock also comes from highly graded free range welfare farms and this ratio looks set to increase as market demand for it rises.

Compaxo’s success, despite its many challenges, seems certain to continue. Though a relatively small business, the wealth of experience and the quality found within will guarantee a bright a future. Gerard, concluding, agrees: “The economy is in difficult times, and to get through that you have to invest and keep the market in your hands. That is what we are doing.”